|

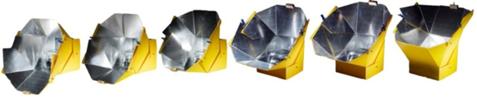

Box without reflectors/Box with reflectors/ Box without reflectors Box-type cookers are very old and one of the most popular at present. The very first design of box-type cooker was supposed to be that of Nicholas-de-Saussure (1740-1799). It was simply an insulated box with glazing; this forms the basis of all the present designs of box-type cookers including Warenham’s (1995) ‘Sunstove’ (Type BWM 1d). The cookers presented here are classified on the basis of reflectors, as those without reflector mirrors and those with mirrors. The cookers of the second category are further divided into five groups based on the number of reflectors as summarized in chart Ib.

Please add, Solar or Solar Cooker, in the subject to avoid your mail being erased as spam Nicholas-de-Saussure design (Type BWM 1, Figure 39) was probably the first solar cooker to appear on the scene in the 18th century (Walton 1977). It was simply an insulated box with two glass panes forming the cover. Vaughen (1979) has recommended such a box with a slight difference. It is a typical box type meant for villagers. A rectangular pit is dug in the ground, suitably insulated with hay or rice husk, and a box not taller than 10 cm made of metal sheet is fixed into this pit, and then covered with two glass panes with about 2-3 ½ cm space in between. Such a cooker would work well,in most parts of the sunny country, such as Africa and India, at least during summer, but to increase the efficiency it would be essential to add a reflector. The author’s endeavours with solar cooking started with a similar design but the box constructed with mud above the ground. Round Aluminium boxes painted with balckboard paint acted as cooking vessels. Results were good, though at times the rice cooked was rather bland, indicating lower temperature, may be due to passing clouds.

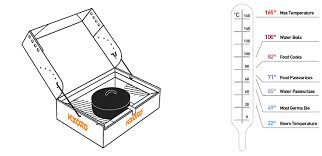

Larger versions of such box-type cookers are being tried out successfully (Nahar et al. 1996; Singh 1993). The Chinese type (BWM 1b) and Brace Research Institute Designs, called food warmer (BWM 1c) (VITA 1961) appear to be similar designs. The food warmer, with better insulation and triple glazing, is still popular (Warenham 1995). Kumar, Kishore (1994) have made the box circular. Many other minor variations are reported, even for the cooking vessels, fixing knobs for the lid and ‘ears’ for the base, making the lid of the vessel concave (Arora, Sharma 1993). Some more design modifications will be discussed later in the text. The nineteenth century cooker of Herschel (Type BWM 2) was probably built on similar lines (Meinel, Meinel 1977). The box was buried in sand and covered with two glass panes, stagnation temperature of 116oC was reported. It is on record that certain nomadic groups of Saudi Arabia bury the food under the sand for cooking (BWM 3). The author feels that they could get their food cooked more reliably if they cover the area with a double glass dome (with the space in between vacuumed) with a knob for easier handling (Type BWM 3a, Concept VI, Figure 40).

This vacuum enclosure, Concept VI, was proposed in the year 1982 or so by me. But I do not think Mr. J.Samalea of Spain was ever aware of it. But the concept of Vacuum as a good thermal insulation is indeed very old, in fact older than Thermos flasks. But only problem was that the technique was never properly applied in Solar Cooker Technology. Now it is J Samalea, who has introduced this concept in Solar Cooking in 2002. His Vacuum Cooker has been announced through Solar Cooker Review of Solarcooking.org. The diagram of the unit is actually taken from Solar Cooker International of Nov. 2003. To know more please visit Salalea’s site http:// cocinasolar.com. ( This comment was introduced on 24th June 2003 ) . The diagram is clear enough, the inner glass bowls are painted black. While outer ones are clear, and in-between them vacuum is created.

Mr Alex Kee of Malaysia, who has been advocating Solar Thermos tubes for water pasteurization,discovered that the stagnation temperature inside the tube could reach up to 2500C. He advocates that such tubes could be used for cooking as well. But the problem is small diameter of the tube. If the diameter of the tube is increased then problems like vacuum sealing will have to be encountered. Once this is solved the Tube cooker would emerge. I advice the reader to visit his site at http://solarwyse.cjb.net/.

Rathinasamy et al., (Type BWM 3 b) have designed a rectangular box from sheet glass, (using popular silicon glue used to construct fish tanks) of 50 x 50 x 22 cm, and under this, the cooking vessels coated with suitable black paint are kept under a temperature of 1100C (Rathinasamy et al. 1988).

Abou-Hussein had presented another interesting variation. Here, the upper part of the box acts as a reflector (Type BWM 4, Figure 41). The window of the box which lets the light in is inclined at 450. The second glass pane is flat and there is ample space between the first and the second glass panes, and this space is used as a reflector. The design is attractive but costly (Bowman, Blatt 1978).

For Comments, suggestions,contributions contact < Please add, Solar or Solar Cooker, in the subject to avoid your mail being erased as scam In most cases, the box is a double-walled container. Depth of the inner box should not be more than 10-15 cm. This depth is a critical parameter, whereas the width and breadth could be of any dimension. The space between these two boxes is filled with insulation, and, the width of the gap varies with the type of insulation used. It would be around 6-9 cm if rock wool is used; it could be a little thinner if fibre glass sheets are used. On the contrary, if low-grade insulation like straw or rice husk is used then the space would be more, about 10-15 cm. Composite insulation has also been suggested by many. In many cases the outer box will be of would and the inner box of sheet metal. In the design recommended by the Government of India, both the boxes are of 16 gz MS sheet. The shape is invariably rectangular or square, but the author has styled the box with slightly tapered base (Kundapur 1995)( Fig 41a ). Bowman suggested the use of foam glass (for box), a robust material which also acts as insulation for making the box, and recently, Warenham (1995) used styrofoam for making a lightweight box. Before going further it is better to ask a question. Which type of Cooker performs better? Card Board or Metal ? Happy finding is that, both perform well and are capable of cooking food. But according to Nandwani et al (1993) Box cooker made from metal sheets attains higher temperatures and performs better. In terms of percentage Cardboard oven’s performance is 15-25% less. Several types of paints are suggested for the inner surface of the inner box to increase absorptive efficiency; blackboard paint was most popular. Yanthra Vidyalaya, Bardoli, recommends boiler interior paint, while Shanmugam et al. (1982) suggest special absorptive coating which would reduce cooking time by almost half. But if foam-glass is used there is no need for any paint. In some of the the designs, especially that of Musumdar’s the inner as well as the outer box are made of corrugated cardboard. Sharma, Philip (1992) also made a cardboard box cooker and used crumpled old paper for insulation. Cooking has to be done in special vessels with tight-fitting lids. Round Hindalium boxes which are available easily in the market were found best but a knob has to be fixed for the lid and two ‘ears’ (handles) have to be fixed to the base such that the boxes could be easily handled. A good pair of tongs also becomes essential to handle the hot vessel; it could form a part of the solar box-type cookers and the manufacturer should be compelled to provide one good pair of tongs with fairly broad and flat gripping surface. Most of the designs incorporate a double-glazed door on top of such an insulated box. Slight uneven surface between the upper part of the box and the door could be taken care of by strips of felt/cloth. The Government of India recommends toughened glass for the glazing, but the author found that the ordinary 3 mm glass also works well, however, it is safer to use toughened glass. The space between these two panes of glass is also critical, it should be just about 2 cm. Shanmugan et al. (1982) suggest the incorporation of a flat square steel sheet just below the second glazing, this sheet with special absorptive coating acts as a heat collector and transmits heat to the vessels kept just below it in the insulated box. The advantage of this design is that the cooking vessels may not require any coating. This is a plus point, for, in an ordinary box-type cooker the vessels are painted black, and the coating wears off on washing (Type BWM 5, Figure 42).Besides the vessels always look better without black paint on it. This is a very promising variation. Further, it may help to reduce the cost. Addition of one or two reflectors would indeed make this cooker very effective.

Fatangare used Fresnel lens in the lid of such a box ( Type BWM 7 ). Results are not known, but guess there will be too much of heat on top of the vessel I feel this part of the review will not be comple if I fail to mention locally designed Box Type Cookers. The photo bellow is from Africa and a Bamboo Box is used. Similar Cookers are in use in other parts of the World.

A visiter to my site wrote to me that I should include brief bigraphical sketchesof famour Solar Cooker inventors, designors and propogators. I would behappy if reader could guide me to the source. But here I am happy to includea picture of Mrs Barbara Kerr along with another Inventor Mrs. Sherry for the benifit of readers. I wish create a special section to include all (big or small) organizations or individuals who are doing excellent work in actively spreading Solar Cookers in their region or accross the World.

One more design which caught my eyes in the SCI collection was, Triangular Solar Cooker. Details were not available.

Suresh Vaidyarajan - an architect, presents a brillent idea, he converts an old tire as solar cooker. It may take a little longer time to cook food, but it is effective. Take a old discarded tire, place a slightly modified Aluminium foil (suitable enough to hold your cooking vessel) load your cooking vessel, prefarably with a glass top, and cover the assembly with a glass sheet. Well if you do not have 2 hammers, don't worry, you can also use stones to prevent glass sheet from blowing away by wing.

Designs like this would be very useful during emergencies, and I feel this or other such designs should be included in all disaster management instructions. In fact, plane glass sheets can also be used as reflectors, in the absense of mirrors. May not be as effective as mirrors, but they would work, especially in emergencies. Reflectors were added to increase the efficiency, and hence, the reliability of the simple box-type cooker. There could be one to four or eight such reflectors. Further classification of these designs is based on the number of reflectors. The author’s earlier work had designated these as SM, DM, etc. but now a new code is used starting with ‘B’ for box-type cookers, and thus, BSM would designate box-type cooker with a single reflector. Box with single reflector Conceived by M K Gosh in 1945 (Gosh 1973), this cooker, known as the Gosh cooker, has become very popular all over the world. This design designated here as BSM 1 (Figure 43), was a typical box-type cooker with a double glazed cover (second cover) and a single reflector which doubles as another protective cover (first cover). The reflector could be held at a proper angle by a ‘kamani’ that is a bent iron rod with a slot in it, (popular in the market as a device to hold the steel window panes). Many found this rather cumbersome and even difficult. Pandya (1983) suggested a 2 cm iron flat with a couple of notches at the base. But the author feels that a longer iron flat of 2cm, with a couple of holes in it would be better. Such a bar can be fixed at a higher level on the reflector door for greater stability. Further , in many designs the peg to hold this bar is fixed on to the main box. But the author suggests that this peg should be on the second door/cover which has glazing, an arrangement which would render easier operation and handling of the cooking vessels (Figure 44).

In 1980, I modified the Gosh type design, the following figure presents the design details. The weight of the Cooker was just about 16Kgs. Boxes were made from 24 gz Galvanized Iron sheets, with fiber Rock Wool insulation. The glazing door had 2 glass sheets of 3 mm, (For glazing, I had also used one glass and one clear polyester sheet, with good results. But the polyester sheet did not last long. Recently, FSEC group suggest Polycarbonate sheets for the purpose) and the lid had a Mylar reflector. Temperature reached was over 1200C. Food got cooked well. But the Mylar reflector did not last long. Cost of production of the cooker was about Rs 300 (about $ 15) in 1980.

The Gosh design has seen many other variations and modifications, Hoda (1979), Garg (1978), Kundapur ( 1980 ),Pandya (1983), and scientists of Bardoli (Parikh, Parikh 1976) have suggested several improvements (type BSM la, lb, lc,). Garg (Type BSM 1d) has fixed the glass door at 450 like that of Abou-Hussein design (BWM 4). Another improtant variation was the provision of two or three holes in the glazing for easier handling of the cooking vessel (Grupp et al, 1991). Concept VII proposed by the author is yet another variation mostly in design. The inner and outer boxes, made of 18 gx GI sheets are stylized, with 5 cm mineral wool insulation and double glazed second door and a reflector first door made of exterior quality 4 mm plywood. The reflector door was further strengthened with strips of wood on all sides and reinforced with aluminium beading. This design weighed only 14 kg as compared to the 25 kg standard design of the Government of India. Except for the aluminized polyester reflector attached to the door, the cooker lasted for several years. So, with a glass mirror reflector the cooker can be as good as any other box-type cooker. Phillip et.al ( 1990 ) have published one of the best papers describing their attempt to reduce the weight but at the sametime trying to maintain the efficiency. But as Bowman suggets to do this Foam Glass is the best alternative. Encouraged by the performance and ease of the Gosh type of cooker, successful attempts have been made to build large cookers to cook up to 20-25 kg of food (Singh 1993); Nihar et al (1996). An electric booster has also been suggested (Arora, Sharma 1993). Kishore and Kumar ( 1994) have presented an interesting variation, the box is round can take only one cooking vessel and this has a small contorted reflector on one side. The reflector seems to have a fixed positon. If the cost of such cooker is low, one can buy three or four such smaller cookers to cook various types of dishes. ( Fig 44a )

For Comments, suggestions,contributions contact < Prof.Sayigh et.al.,(1998 ) have come out with a new design in which THREE glazing sheets are used, The 2nd and 3rd glazings are just above the cooking box while the first one is placed much above the 2nd. The gap has a reflective coating. The 3rd Glazing is 5 mm thick glass.The box has a drawer for cooking vessel, this reduces heat loss.The cooker has one reflector and hence has been classified here as BSM 3. Overall performance appears to be very good. The model is being popularised in Indonesia. ( Fig 44a ) Recently, El-Sebail (1994) proposed a new design which appears to be interesting. The box is with double glazing, and the interior has reflector surface set at different angles to focuss the sun light on the vessel The vessel is placed on the stand to meet the focus ( Fig 44b )

ULOG group of Switzerland has modified the box design to suit for temperate regions, by inclining the opening of the box as shown in the photo. Their cookers are very good and the group is dooing the good work of popogating Solar cooking in continents like Afrika.

IMPORTANT NOTE Regarding the fabricating box type cooker of Gosh type Solar Cookers, for making the box, Prof. Barbera Kerr and several others had suggested using card board, or even mud walls. Metal sheets from printing press can also be used. As to insulation, paper balls, straw and a wide variety of locally available materials can be used. Inventors like Patel ( 1981, Ref. 74, ) had infact suggested inverted Glass Jar in stead of a very heavy and combersome insulated Box. In fact this concept using glass jar around the pot could be traced back to Adam in 18th century. Later Prof. Bernard too suggested the use of such a Jar for his 'COOKIT' design. Glass Jars are costly and are prone for breakage so Prof. Barbera Kerr used clear plastic bags to cover the cooking pots very successfully. Prof. Bowman too had realised the importance of the insulation of Cooking vessel and he had suggested FOAM GLASS boxes around cooking pots for the FIT designs. Unfortunately FOAM GLASS has not not become popular in solar cooker. I really wonder why. Recently Deris uses two such clear jars ( Glass or heat resistant Polycarbonate jars ), inverted over the cooking pots where the light is concentrated by a circle of ordinary mirrors! I guess the solar Cooking can not be made simpler than this. At this juncture I wish to introduce the work being pursued by Late Prof. David Delaney of Canada. Taking the cue from Prof. Bernard, and Barbera Kerr he is attempting to improve this Glass Jar concept. Covering the Cooking pot with a Glass jar has two problems, handling the cooking pot and its contents become difficult, and condensation of moisture inside the glass container affects the transmission of solar light to the pot. So he suggests use of a upright jar of not more than 2 inches in diameter of the cooking pot. Use of a suitable collar of card board or more stable material for placing the pot into the jar, and also a cooking pot with a clear glass 'insulated' lid. I feel that these suggestions are very apt, but at the sametime find that the Glass jars of that type are rather costly upto Rs. 400 ( $ 10 ) especially because Gosh type Solar Cookers of 2' x 2' were being sold in our country at Rs. 450 to 650! ( $ 12 to 16 only ). I am not suggesting that the Box type of Cookers are better, but an attempt is needed to find a suitable material to cover the cooking pot.Davids work has been detailed in previous section,viz.,light from above ( solar 6 ) I consider suggestions of Diasanna from Nigeria as the best alternative, more about this later under next section on Panel cookers. Syntex Plastics of India has come out with a all plastic Solar cooker of this type, of course metal cooking pots inside. They are using PUF insulation,I guess, but the details were not available. The selling cost of Rs. 1000/- is rather high. Mr Rohatgi has come out with a FRP Cooker Late.David has tried out a new variation of Box. Realizing that some heat is lost from the double glazed door of the box, he has tried to INVERT the box, so that the light strikes the vessels from the bottom.The top now has an insulated cover which can be easily lifted to check cooking. Reader is advised to visit his excellent site, listed under links (solar16) of this site.

Prof. Ajay Chandak of India has improved on this design. Ajay uses three reflectors at the bottom and one reflector at the top. He report that initially he had problem with so much heat that the glass broke. Prof Ajay is doing excellent work of popularising Solar cookers in India. His another invention Balcony cooker has been mentioned under parabolic reflectors.

Dr.Muhammad Yasin Khan of Pakistan, has come out with a new design of solar cooker, which I consider as original and new. The center of his cooker is a metal box with door on one side like in a microwave oven. The box, painted black, is covered with double glazing. There is a bigger reflector on top and a smaller reflector at the bottom. Khan reports good performance.(personal communication of 8th April, 2007)

In fact, these two modifications should have come later

under different section - viz., box with three mirrors. But

as I started with Late David's design, I continued with the

other two modifications.

Box with reflectors continued Box with four plus four reflectors The Gosh type cooker would work well during summer in most part of India but Reflector during winter, at least in north India, additional boosters would be essential and this has resulted in the development of the box-type cookers with double reflectors. In Type BDM 1 (Figure 45) Agarwal adds (1981) another reflector at right angles to the first, his drawings do not suggest any mechanisms for tilting, which would be essential. But een without such tilting mechanisms Agarwal reports faster cooking during October. In Type BDM 1a, (Concept VIII, the author suggests two reflectors, both with tilting facility. This design worked well reducing the cooking time (Figure 46). Concept IX, Type BDM 2, (Figure 47) presented by the author in this review envisages incorporating the cooker with two reflectors inside the house as illustrated (Kundapur 1995). Advantages are many and it is very easy to incorporate the cooker in the house. In our country lowery easy to incorporate the cooker in the house. In our country low-roofed huts are common and in all such cases this design could be used.

The author feels that even in multi-storied buildings, such extensions could be provided in every floor at proper height to place this type or other designs of cookers, such that, cooking could be done from inside the house.

The above concept was conceived by me during 1980's but I do not wish to make any claims on the same. I note with interest, that such a design is now being used, and finds a mention in SCI site. The Wall Oven found at SCI site is of this type, but only difference is that it does not have a reflector where as my design has two reflectors. it is suggested that solar Cooker enthusiast and designed Mrs Barbara Kerr designed this type of Cooker. Later, probably it was Prof. Paul Funk who set it up.

Wall Oven ( Source SCI site )

In this type of cooker, one of the reflectors has to be adjusted seasonally while the other requires daily adjustments. In Cheema's ( 1984 ) design the lid opens to form double reflector one above the other. Prof. Cheema had presented an interesting variation ( BDM 3 ) as early as 1983. This is a double reflector design one on top of the glazing and another reflecting the light through a side window. The arrangement appears to be interesting and Cheema reports a stagnant temperature of 206º C compared to 164 º C of ordinary cooker.

Sri. Sankha Subhra Datta of Jalpaiguri, a sub Divisional town of West Bengal, has come out with an ingenious new concept for Box type Solar Cooker ( Designed by him in 2002 ) . I consider it as a new major Design on the scene and designate it as BDM 4. It is a rectangular construction with two reflectors, making it possible for trapping maximum Solar Radiation. For achieving this the Cooker has to be inclined and while doing so to prevent the cooking vessel from spilling over, he has positioned them on tilting stand. There are 4 such stands for 4 cooking vessels of 1 lit capacity. The inventor report that the water reached boiling point with in 105 mins, stagnation temperature recorded was in the range of 1480C . There is provision of for adding two more reflectors if need be. The cost of construction is estimated at Rs. 2000/-. I am sure this Cooker performs better than regular Ghosh type Box Cooker with one reflector.Following photo sent by the author is good enough to show details. For further details one could contact sankhasubhradutta@yahoo.com

Recently Mr Terry Jantzi of Canada, has presented a double Reflector design. The cooker box is round at the bottom, making it easier to track the sun. The reflectors are hinged to the box and are held in position with flat belt like strips. Mr Terry can be contacted through tjantzi@p3tek.com

A company from Europe is is marketting a double reflector cooker, as shown in the following photo.

To improve the performance further three reflector designs were proposed and the Reflectors Concept X (Type BTM 1, Figure 48) proposed by the author does just that. Two configurations were tried, they did not, however, reduce the cooking time by one thirds, besides, adjustment was also cumbersome. Of the two proposals, the one with configuration 2 was better. The reflectors could be adjusted and tilted individually after setting. The box has to be turned to face the sun. the space between the mirrors could be fitted with triangular mirrors to increase the efficiency further. It is further proposed that these additional mirrors would come as ‘add-ons’ (to reduce cooking time) rather than as part of the cooker.

The above photo is from SCI site, but I could not get to the details regarding the Scientist/inventor and test results if any. Better and ideal configuration could be to have a two triangular reflector adjacent to the main reflector as shown in the diagram. As Prof. Bowman had observed a triangular reflector casts a better image on the cooker. ( Fig 47b )

Box type cooker with three reflectors are available in the market

Details and principles of the design. ( source SCI ) Halacy (1974) had gone a step further by suggesting a cooker with four reflectors (Figure 49). Bowman, Blatt (1979), who tried to build such a cooker, found that adjustment of the reflectors took a long time and required several supports. The cooking time was not reduced by one-fourth as compared to the single mirror cooker. However, it is essential that a designer know about the existence of such a design, as it would avoid any further attempts in designing such a cooker.

Recently this design, namely Halacy type 4 reflector seems to have surfaced and we find it being referred to in Solar Cooker International (SCI) site.

Halacy type Cooker ( source SCI site )

Box cooker with 4 reflector is now being marketted in USA as

All American Solar Cooker

The Kyoto Solar cooker, which has become popular recently, and which is being advocated activley in Afrika, is basically a box type with 4 reflectors, but made from local materials.

The 2nd image shows a box made from polypropelene sheets, in a style like we see it in recent packaging boxes. There is another interesting variation by Paul Hedrick. It is indeed a hybrid between Box and Panel cooker. This cooker has a box made from thin fluted Polycarbonate sheets, to house the cooking vessels. Paul can be contacted through paul@solarcookers.org

Box with four plus four reflectors Maria Telkes (1959) was probably the first lady to design a solar cooker, Reflectors popularly known as the Telkes design which was one of the best in the series and could develop a temperature of 2250 C. The box was a rectangular double-walled insulated box with a door on each side. The box had double glazing fixed at the top, and the there were four main reflectors set at an angle of 60o to the horizontal. The corner spaces between these main reflectors were fitted with four triangular mirrors. The insulated box had a cradle frame to hold the cooking vessel and to assist in tilting. The whole cooker was mounted on to an ‘A’ type frame. Hoda (Type BFF 1a) suggests some improvement in the stand to reduce the cost. Type BFF 1b, designed in Senegal, has a funnel – like reflector. Telkes also suggested a modification such as a box with an aperture set at 450. Bowman, Blatt (1978) tried to maximize the dimensions of the Telkes cooker. The outer ‘A’ type of stand was eliminated, but the inner cradle was retained. Alzek reflectors were used instead of glass mirrors. A new type of insulation material foam glass was used to make the box. A temperature of 2250C was reported (Figure 50). The author tried this variation, that is concept XI, here at Udupi, but as foam glass was not available, a box of GI sheets was used and insulated with mineral wool. Regular glass mirrors a transparent PVC sheet was used on top. To effect the tilting, a steel frame support was incorporated. The assembly worked well but compared to the single or double mirrored Gosh type design the cooking time was not reduced to one-fourth as expected. (Type BFF le, Figure 51).

As the Telkes design was costly but more efficient, Rose (1981) of VITA designed a cooker based on similar design but with cardboard (Type BFF 1f). Muzumdar (1980) made a similar design also with cardboard, but the box had only a single polyester sheet as glazing, the reflectors were also made of cardboard and coated with aluminized polyester. The cost of the unit was claimed to be just Rs. 95/- (Type BFF 1g). Type BFF 1h is a patented design from the US (Patent no. 4 292 957). Weyer (1980) uses GI sheets as reflectors (Type BFF li). November 2004 issue of Solar Cooker Review (SCR)of SCI has many new designs of Solar cookers. Eye catching design was from Italy. The designer is Mr. Gianni Crovatto. I would consider it as highly developed Telkis design, and would classify along with it. Prof. Bowman probably was first to modify Telkis cooker, then I tried to take off the ‘A’ Stand and suggested a alternative. Mr. Crovatto, has gone further in making the reflector more elaborate so as to direct more sun rays into the cooking pot. The two pictures enclosed here are from SCR. His excellent Web site is found at http://digilander.iol.it/giannicrovatto

Jim La Joie of California, has designed what is called as All Season Solar Cooker. The Box which has an inclined opening is surrounded by 4 + 4 reflectors. Interesting part of the design is the reflectors can be moved to 'track'the sun easily for all season or angles, while the box with the cooking pot does not change the angle, so there is no need for a 'cradle like' stand inside the box. It is one of the best design I have come accross. I think this design could well be considerded as FINAL in Box cooker design. For details you can visit http://www.allseasonsolarcooker.info/solar-cooker-plans/

Many solar cooker enthusiasts have asked me as to the best method of finding out the right angle for reflectors. Whether they are reflecting adequate amount of sun light to the pot and so on. As regards this, many suggestions are there. Best possible answer is of course to test the cooker in a Solar Simulator. Prof. Bowman had suggested another easy method. Try to put your head in the position of Sun over the cooker, if the Cooking pot ‘fills’ the reflectors, then the position of reflector is right. Other method, though cumbersome, is to use a small Laser light. Flash it over the reflector from all possible positions of Sun, and see where the reflection is falling. Inverted triangular Reflector, (with base at top ) perform better. While adding more reflectors, one should keep in mind the area also. For better efficiency and performance Sun from a larger area has to be concentrated. In other words there is no point in designing a perfect concentrating array of mirrors for, say half-a-square meter and expect a lot. Getting more power means capturing/concentrating sunlight from larger area Recently another interesting design has emerged on the Solar cooker scene. It is known as 'Fortune Solar Cooker'. Enthusiasts like Leon Simons and his group have designed this promising design. The concept appears simple enough, but the possibilities are excellent. One can cook it from the comforts of their balcony or even kitchen, provided of course sun shines at least for a couple of hours inside. The drawing is self explanatory. And their web sites suggest that a larger oven can be easily fabricated. May be it would be possible to increase the capacity of cooking as well, to a certain extent at least, by increasing the size of main reflector. Now that Solar marker is 'blessed' with reflective plastic films, the unit should be within the reach of common man. The Solar Panels there are added novelty I guess, available for extra cost - not sure. But I guess an additional reflector can be attached here to get more power. You can visit youtube for a demo (https://www.youtube.com/watch?v=zRaQdWaNNEw) and reach their sites through Google This as well as the hybrid cooker of Paul, mentioned above are technically not Box cookers, but they look like one, hence I have classified them in this section.

NAVIGATION CHART.

OTHER LINKS

are listed

under S11-References A to W

For details

regarding testing standards for Solar Cookers ( International

Standards ) please

click here

For Comments,

suggestions, contributions contact

Dr.

Ashok Kundapur

Email :

Please add Solar or Solar Cooker in the subject to avoid your

mail being erased as spam

|

|||||||

For

details regarding testing standards for Solar Cookers ( International

Standards ) please

click here

For Comments,

suggestions, contributions contact

Dr.

Ashok Kundapur

Email :

Please add Solar

or Solar Cooker in the subject to avoid your mail being erased as

spam